Instrument Design

Instrument Design in the context of hardware refers to the process of creating precise, functional devices and tools used for measurement, control, or data acquisition in various fields like electronics, engineering, healthcare, and research. This involves defining specifications, selecting appropriate materials and components, and designing both the physical structure and the embedded systems that control the instrument’s functionality. The process requires close attention to accuracy, reliability, and user interface design, ensuring the instrument performs effectively under specified conditions. Instrument design often includes iterative prototyping, testing, and refinement to meet performance standards and industry regulations.

Instrument Design in hardware, the process begins with identifying the specific requirements for the instrument based on its intended application. This could involve measuring physical quantities like temperature, pressure, voltage, or flow rate, depending on the industry—whether it’s medical devices, scientific research, industrial automation, or consumer electronics.

The next phase involves conceptualizing the design, which includes:

- Mechanical Design: Determining the physical layout and structure of the instrument, including the housing, buttons, displays, and ergonomics, to ensure durability and ease of use.

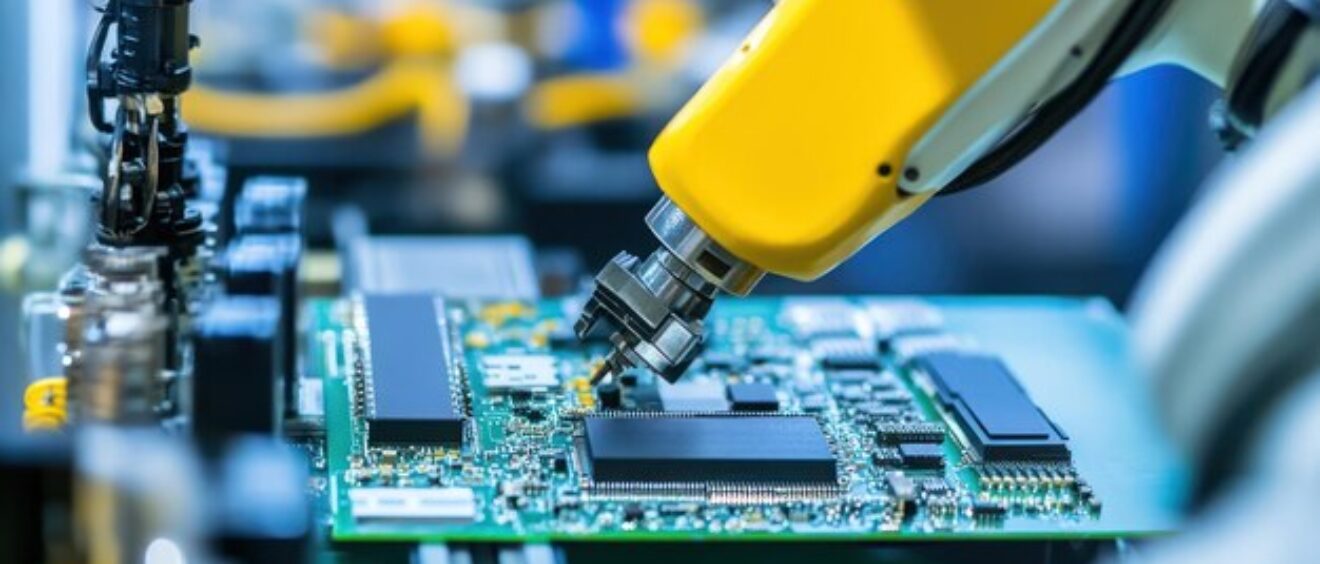

- Electronic Design: Selecting and integrating sensors, microcontrollers, signal processing units, and other electronic components to handle data collection and processing.Firmware/Software Development: Developing the embedded software that controls the instrument’s operations, such as data acquisition, processing, and communication with other systems.

-

Prototyping and simulation tools are used to validate the design before moving into manufacturing. Precision and accuracy are critical, especially in fields like healthcare or aerospace, where even minor errors can lead to significant consequences. This is followed by rigorous testing for environmental durability, calibration accuracy, and compliance with industry standards like ISO, CE, or FDA regulations.